Toprock® Tapered, Flute Filler and Cant Strips

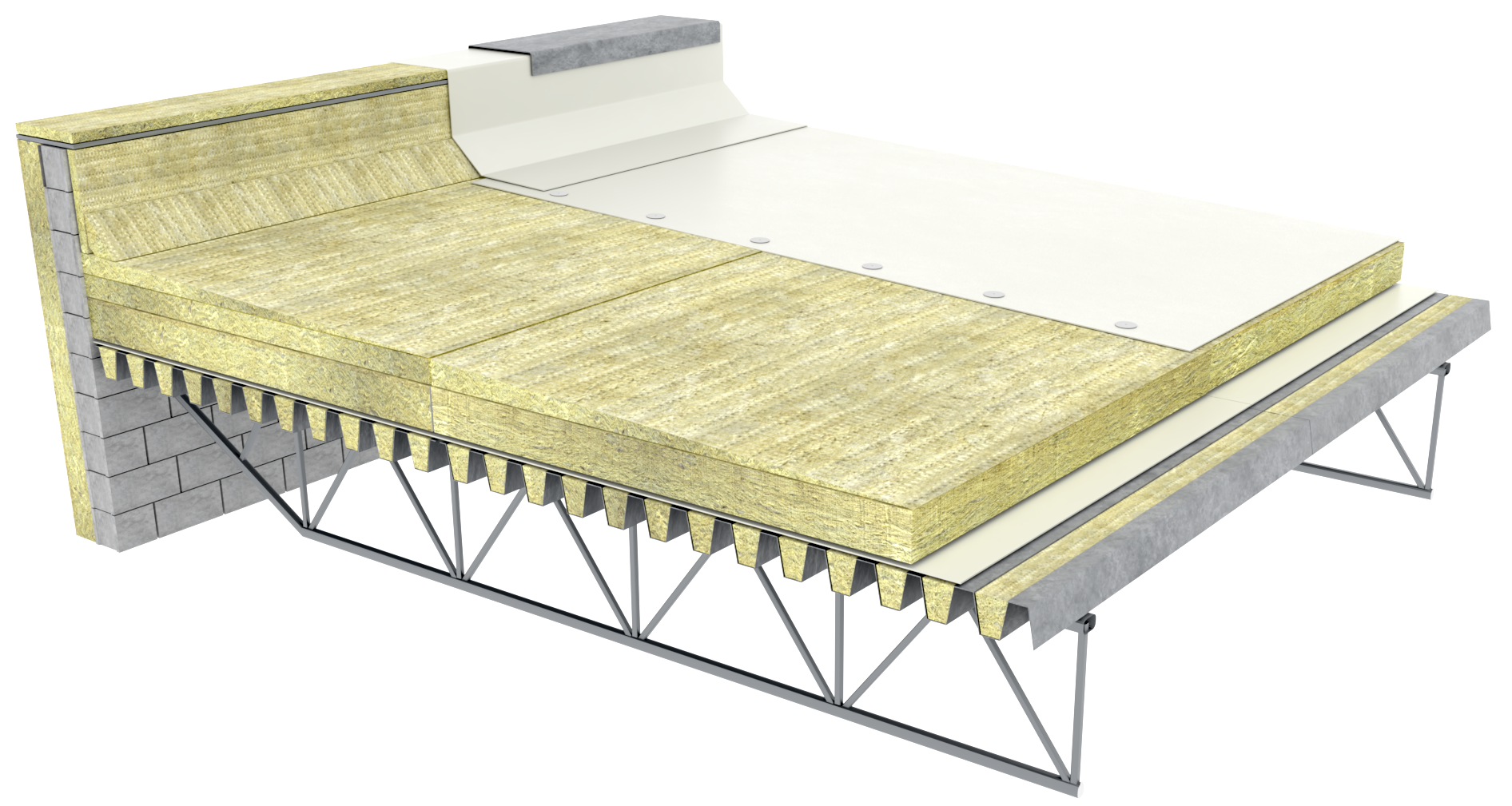

Fabricated stone wool insulation components for low-slope roof applications are engineered for compatibility with a variety of membrane types, air/vapor barriers, fasteners, and adhesives, for both new construction and re-roofing applications.

1/2

Popular applications

- Roof insulation

- Low slope roof insulation

About Toprock® Tapered, Flute Filler and Cant Strips

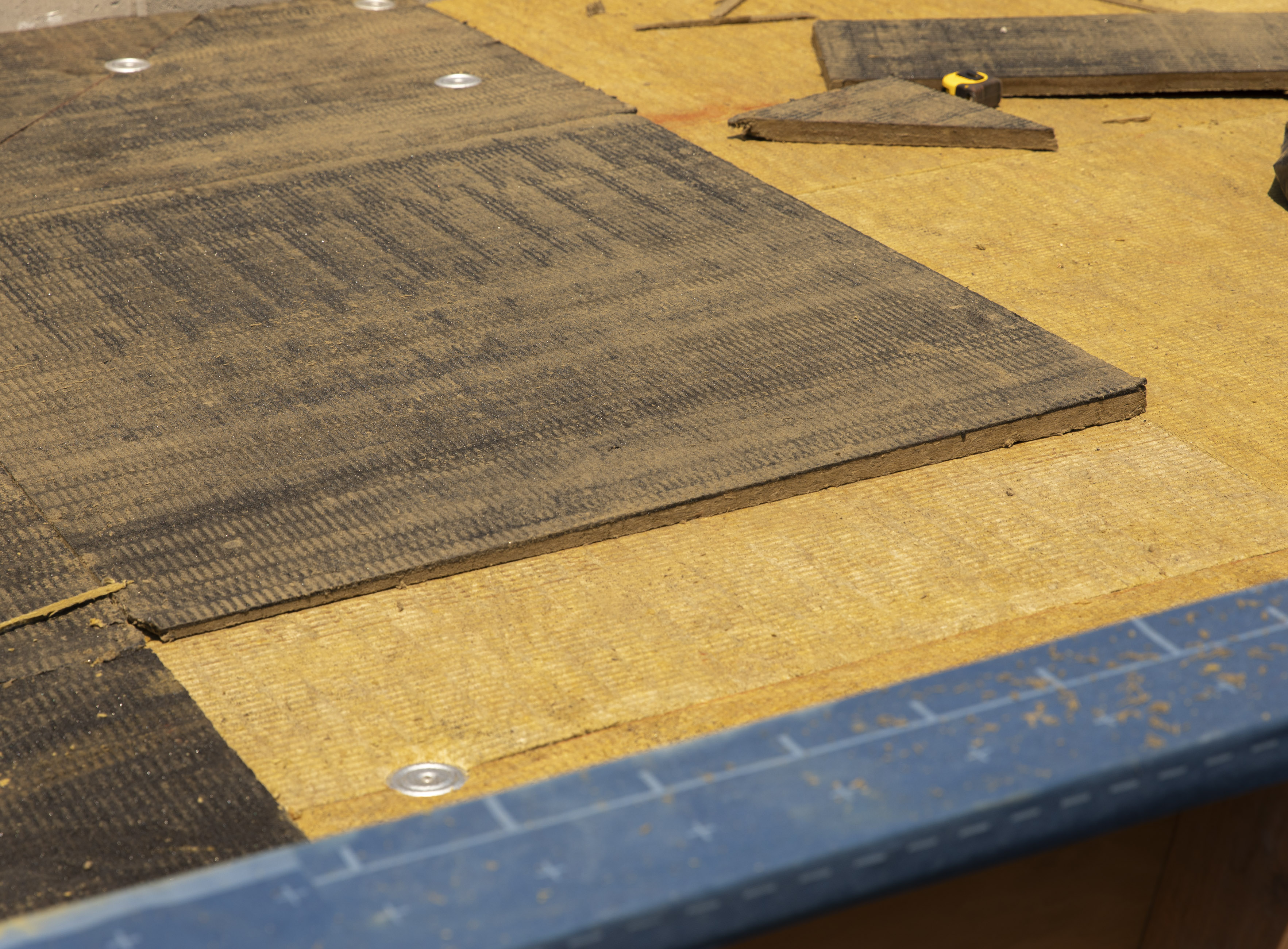

ROCKWOOL Toprock® Tapered, Flute Filler and Cant strip fabricated components are cut from high-density stone wool roof insulation that will not warp or cup. The low co-efficient of linear expansion of this material means less movement during temperature changes and no shrinking over time that could otherwise cause energy loss.

Toprock Tapered products are available with and without a bitumen facing, and are engineered to ensure positive drainage and avoid ponding.

Toprock Flute Filler inserts into the void of standard metal deck profiles to absorb noise and incidental sound.

Toprock Cant strips are available with a bitumen coating to provide transitions from horizontal to vertical surfaces.

- Noncombustible and fire resistant

- Dimensionally Stable

- Sound Absorbent

- Water Resistant

- Ease of Installation

- Stable R-value

Why use stone wool insulation

- Noncombustible and fire resistant, stone wool works to contain a fire and prevent its spread.

- Stone wool will not expand or contract with changes in temperature, minimizing gaps and providing consistent energy efficiency for your building.

- High-density insulation offers improved sound reduction, helping dampen outdoor noise and rainfall.

- Will not absorb or adsorb moisture and increases the drying potential of the assembly.

- Cuts easily and cleanly with a serrated blade to produce precise, straight lines and lays flat with a seamless fit.

Applications

- Designed for low-slope roofing applications to support full assembly design.

- Compatible with a variety of membrane types, air/vapor barriers, fasteners, and adhesives.

- Can be used in both new construction and re-roofing applications.

Product certificates

UL Classified - CA/USA

UL Classified - CA/USA- FM Approved

Specifications & testing

Explore Toprock® Tapered, Flute Filler and Cant Strips specifications and test results, based on relevant industry standards.

| Name | Value | Test standard |

|---|---|---|

| NCC (Non Combustible Core) Rated Roof Insulation | Passed | FM 4470 |

| Flame spread index | 0 | ASTM E84 |

| Smoke Developed Index | 0 | ASTM E84 |

| Combustibility of Materials at 750 °C | Non-combustible | ASTM E136 |

| Determination of Non Combustibility of Building Materials | Non-combustible | CAN/ULC S114 |

| Fire Tests of Roof Coverings | Class A | CAN/ULC S107-03 |

| Heat Release Rate of Roofing Assemblies with Combustible Components | Class 1 | NFPA 276 |

| Corrosion of Steel | Passed | ASTM C665 |

| Compressive resistance description | Entire Board - 11psi (75kPa) @ 10%, 15psi (105kPa) @ 25% |

Toprock® Tapered, Flute Filler and Cant Strips technical documents & resources

Download Toprock® Tapered, Flute Filler and Cant Strips technical documents and resources, including the product data sheet, to support accurate specification and efficient project planning.

Toprock tapered, flute filler and cant strip components

ROCKWOOL Toprock® fabricated stone wool insulation products are noncombustible – providing increased fire resistance, water resistant, and offer long-term dimensional stability.

Guidelines for cutting stone wool insulation

Properly cutting stone wool insulation ensures fit and maintains performance, preventing safety and efficacy issues.

Dimensional stability of rigid board insulation products

Investigations often uncover irreversible dimensional changes in rigid foam board insulation, like EPS, XPS, and ISO.

Enhancing metal roofing systems with stone wool insulation

Metal roofing panels are structural or architectural, each with unique functions and benefits, vital for building integrity and aesthetics.

Attend a ROCKonnect Masterclass

Earn CEUs and gain expert insights into high-performance building envelope design—all in a live virtual format built for commercial building professionals. Learn from award-winning experts and apply real-world solutions to your next project.